The Realities Of Selling Hardware

The most frequent comments I get about the hardware I sell are to do with pricing, it seems it is a very polarizing subject. Usually, the “too expensive” complaints are from non-purchasers who feel the need to remind me they can get the same from China for a fraction of the cost, the “great value” type comments are from makers who understand what’s involved in small scale home manufacturing.

Let’s take a pragmatic look at the costs involved in producing and selling a small project with a realistic target volume of 50 units.

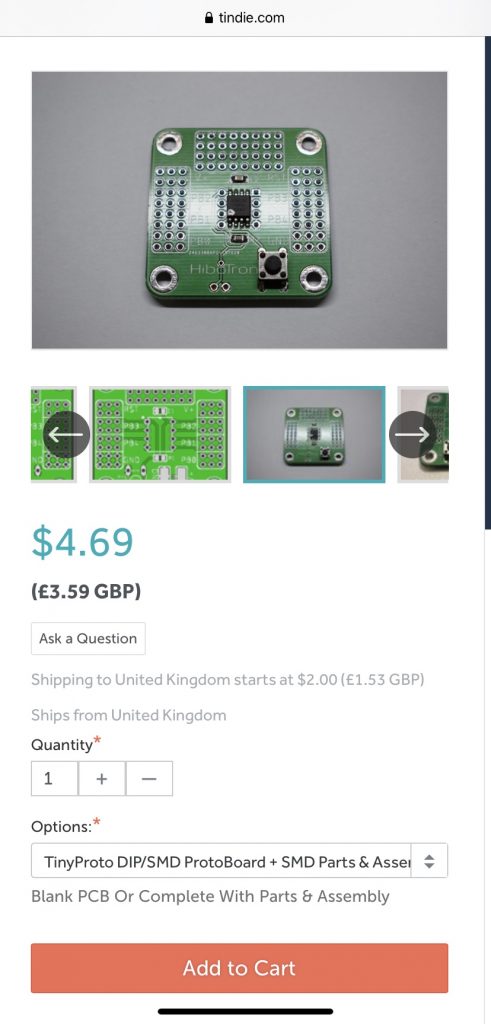

For this example we’ll use my ATTiny Protoboard, the outlet will be Tindie and the shipping costs will be covered by the customer.

The Design

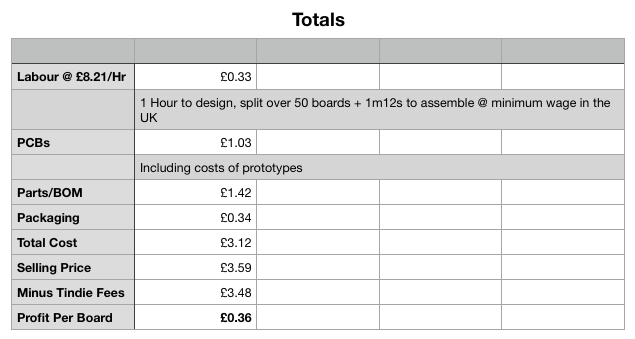

Many people will overlook the time spent on actually designing the product, a simple board like this could be designed and ready for fabrication in under an hour. Many people think the design time(cost) should be swallowed by the maker when in reality we are trying to make a little money to further our electronics hobby.

Fabricating The Circuit Boards

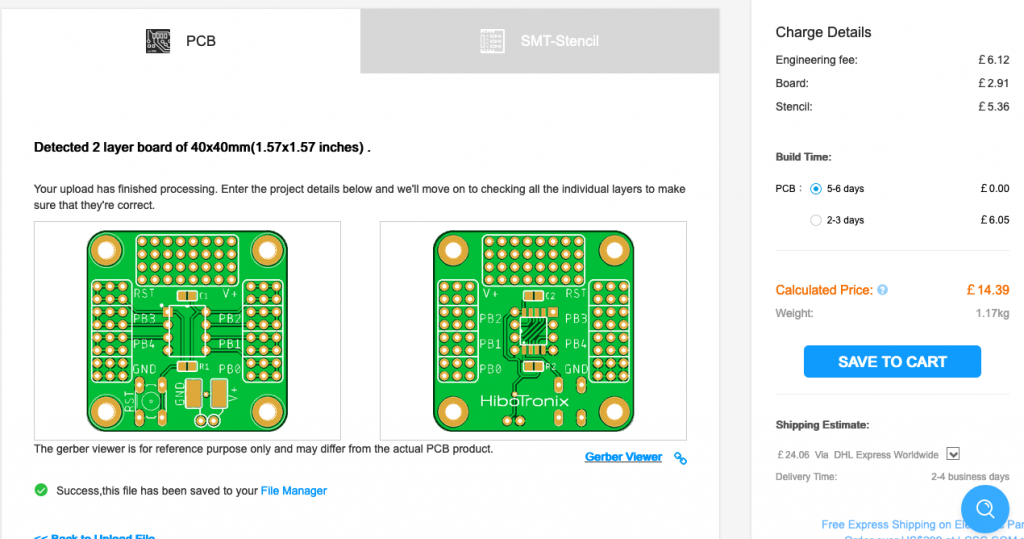

With the ease of direct access to Chinese board manufacturers, these costs have dramatically reduced. In this exercise, we’ll use JLCPCB, but there are many to choose from depending on your needs. Many times you will need a minimum of 2 revisions of the board before they are ready to sell, a good practice is to order 5 for validation before committing to your big order.

The 5 board first revision order costs £8 ($10.45) delivered, for low volume/cost orders I chose the cheapest postage option at the sacrifice of delivery time. The second, ready for sale order, including a stencil costs £38.45 + ~£10 DHL customs/handling charges. So you have your boards whats next…..

Parts/BOM

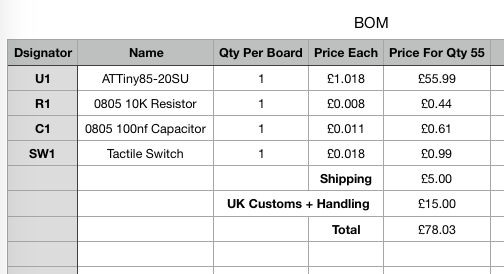

Parts for this project will be sourced from LCSC but I will use a variety of sources depending on availability and shipping cost. Generally, I will try to source all parts from the same vendor to save on shipping costs.

Here is the BOM for this project…

Assembly And Consumables

Another overlooked cost is the time taken to assemble the product and also the costs of consumables used in the process. Once setup I can stencil, paste, place and hot air reflow a board in 1m12s giving a total production time of approximately 1 hour. The main consumables used are IPA for board cleaning and solder paste, I won’t include those in the final total but beware they are finite resources and will need replacing.

Packaging

I send a majority of my orders in a small box with the individual products in small metallised bags for protection. The boxes are approximately £9 delivered in 50 quantity and the metallised bags are about £0.02 each. I also include a custom printed insert that cost £0.14 each.

Adding It Up

36p!!!!

Now a lot of you are probably thinking why on earth would you do all of that for so little return, well the answer is:

- I Love Electronics!

- I have commercial customers who I design boards for so I buy in much higher quantities.

- Quite often i’ll make a board I can’t find in other places or I might have specific requirements.

- I assemble my boards at the same time i’m assembling my commercial customer’s boards.

- I like to try and give back to the awesome community i’ve learned so much from over my career.

The reality is my profit for this board is actually about £1.17, but even if it wasn’t I would still make them.

Conclusion

The aim of this post was not to put you off designing your boards for sale, it was more of a gentle reminder that not all projects you make will sell enough to be profitable and if your sole motivation for selling is to make a healthy living, you need to fully research your intended market, your competition and your projected build costs. The reality is very few makers earn enough to make hardware a full-time job.

For all potential customers out there, next time you need an electronic device, check out places like Tindie, yes you might pay a bit more, but usually, you’ll get a hand-built, individually tested project which was built with love by a fellow maker.

Leave a Reply

You must be logged in to post a comment.